INNOVATIVE CONSTRUCTION TECHNOLOGY BENPAN

Since 2010, we have set a goal to create high-quality, competitive products in the building

materials market, with such qualities as energy efficiency, environmentally friendliness,

durability, quick assembly, and high factory readiness. We have gathered a group of

professionals with specialties, from programmers, structural engineers, and quality control

specialists, and have improved our products for over ten years, creating new types of unique

wall and floor panel designs and equipment for their production.

As a result, we believe we have managed to create a unique product that allows you

to quickly organize the production of reinforced concrete structures for low-rise buildings.

-

DESIGN

-

SOFTWARE PACKAGE

-

MANUFACTURING

-

TOOLING

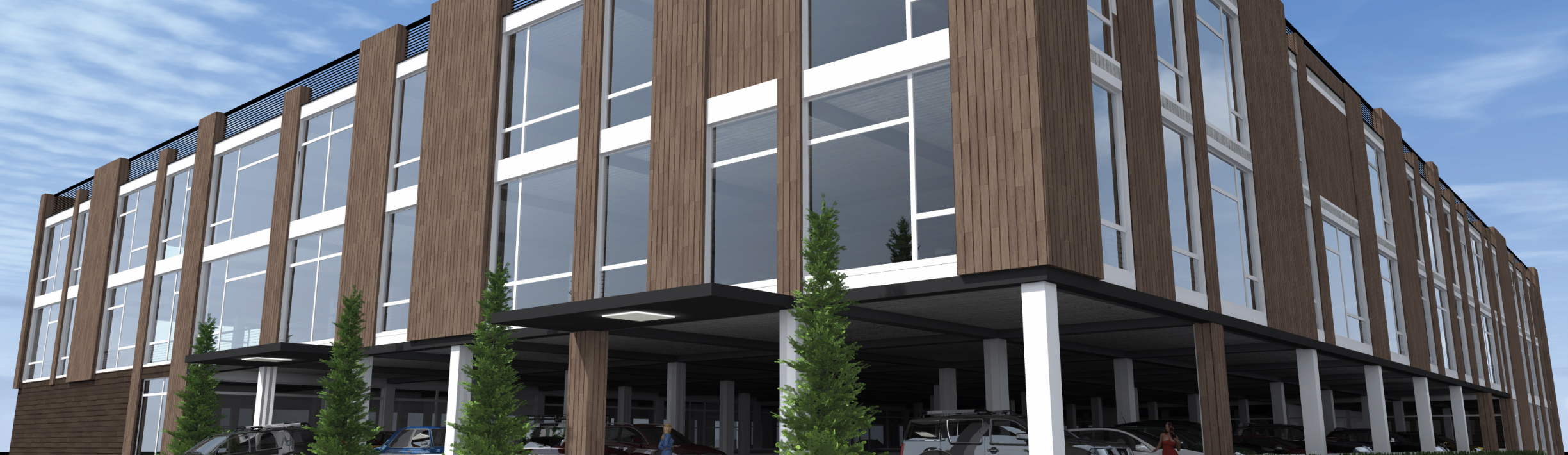

Our products are designed and manufactured individually and have a ribbed structure that saves material by 30%. Using unique technology, we can complete a project of any complexity and format for any architectural design of precast concrete for various types of buildings up to 5-story. Integrated design provides minimum production time due to automation. BENPAN technology delivers prefabricated, energy-efficient, fireproof, fast-erect, and durable houses. The panels are certified, environmentally friendly, highly competitive, and in high demand on the market.

We offer unique advantages over similar types of reinforced concrete structures from other manufacturers. As a result of all the above, the cost and the highly competitive price in the building materials market, another bonus is high factory readiness and quick assembly for any climatic and seismic zones!

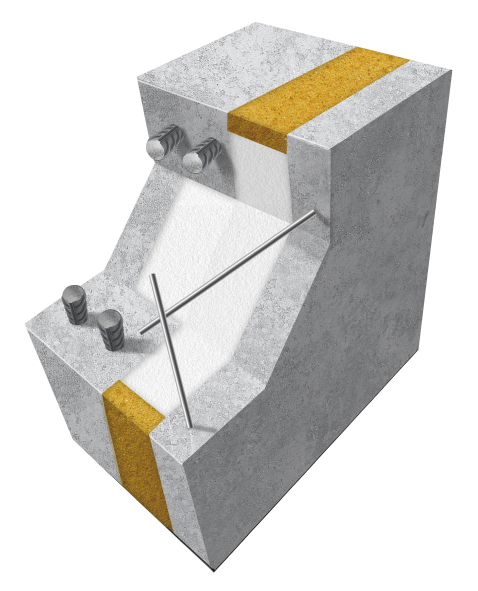

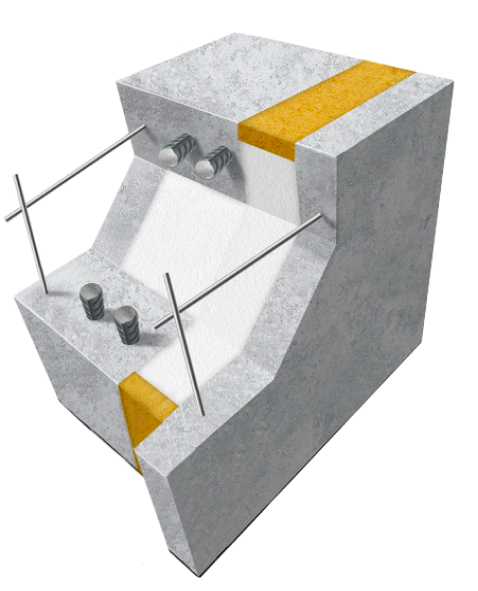

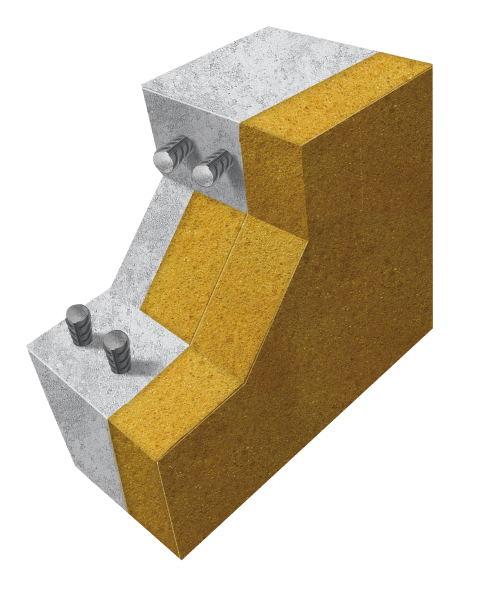

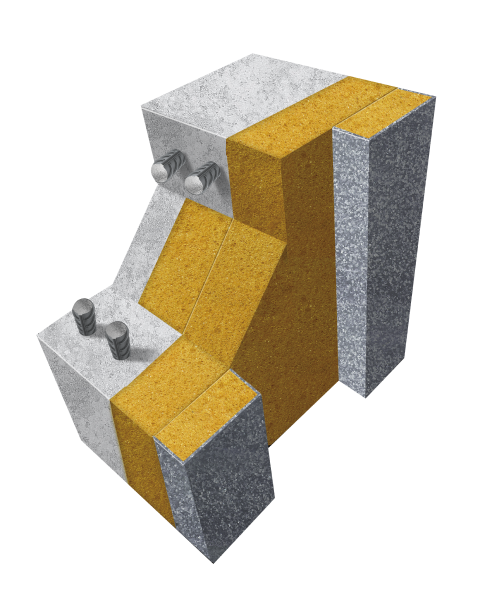

The BENPAN technology allows the use of various types of panel connections depending on the needs and regulations of a particular construction site.

- Use of embedded parts for welding together with a plate.

- Connection with anchors through the plate.

- Joint with Peikko hinges, followed by concrete for a monolithic connection (used in seismic areas or for buildings with special technical requirements).

-

DESIGNARCHITECTURAL DESIGN process 5 DAYS

- Receipt and adaptation of the architectural design project

- Design of an architectural project

-

STRUCTURAL DESIGN UP TO 5 DAYS

- Design of the project and structural elements with the assignment of a unique identification number and barcode for each of the panels

- Panel assembly diagram

- Wiring diagram

- Creating a Packing List

- Creating a general list of all elements for the production of each panel

- Formation of the planned cost of the main and embedded parts

- Export product data

-

PRODUCTIONPREPARING A PRODUCTION ORDER UP TO 1 HOUR

- Task formation for the embedded elements production

- Task formation for the basic elements of reinforced concrete structures production

- Coordination of orders

- Establishment of needs and availability of materials for production

- Provision of materials

- Form to control the reinforced concrete structures assembly

-

MANUFACTURING AND DELIVERY OF PANELS 5-7 DAYS

- Production of panel components

- Panel manufacturing

- Quality control (Form fill-in)

- Creating a passport for each panel

- Materials write-off

- Establishment of the actual cost of production

- Creating shipping documents

- Shipment of panels

The production of BENPAN ® products is carried out mainly on equipment designed and supplied by us and protected by patents. More than 90 equipment and tooling items are used to manufacture products using the BENPAN technology.

The complete set of equipment depends on the types of products and production volume.

-

-

-

KNOW-HOW

-

1

Description of the production business-process

-

2

List of all materials needed for production

-

3

List of all embedded parts (including tech charts and material consumption norms)

-

4

The entire list of reinforced concrete structures (including tech charts and norms)

-

5

Assembly instructions

-

6

Transport instructions

-

7

General information database, including product standards and all necessary information for BENPAN structures production

- Design of any buildings and structures adapted for the production of elements using BENPAN technology

- Training of personnel for the reinforced concrete structures production

- Production management system

- Necessary regulations, technical charts, and norms manufactured embedded parts and reinforced concrete structures themselves

- Technical support throughout the duration of the contract

-

CONCRETE AND CONCRETE PRODUCTS MANUFACTURERS

Modernization of production, diversification of production, expansion of the product range

-

DEVELOPERS, CONSTRUCTION COMPANIES

Set up of own mini production of reinforced concrete structures using BENPAN® technology

-

PRIVATE INVESTORS, LANDOWNERS, DEVELOPERS

The individual investing strategy in innovative technologies